Saturday, March 17, 2007

Friday, March 16, 2007

Thursday, March 15, 2007

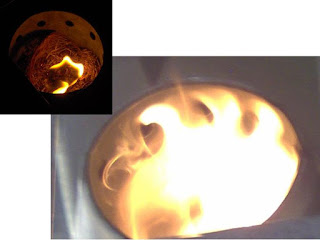

MAGH TWISTER STOVE

This is my new Prototype, named it as 'MAGH (Cloud) TWISTER STOVE'. There are two reasons to develop this model. First, I am fascinated by the Cyclones in which the immense natural draft of the wind power is generated and the second reason is that I was trying to explore the natural means of generating forced secondary air for the T-LUD woodgas stove. The use of twisted fins around a cylindrical fuel chamber, inserted in a cone is helping to create a strong and twisted air flow. The surface area of fins and the surface area of cone is helping the draft air to get heated to higher degrees, therefore hotter air is supplied at the secondary air inlet. The conical shape also reduces the volume of space at the top and also as the air is hotter there will be more pressure generated at the top. The use of a air control mechanism at the bottom is for controlling the amount of secondary air supplied.

The primary air is through small openings created on the bowl located at the bottom, which is connected to a lever. This facilitates the easy batch loading of fuel (small sticks / wood pieces / coir / dry leaves etc.,) from top and the ash can be removed conveniently by releasing the lever.

Among all types of fuels, I found dry-leaves are also well suited for this model for short (10 minutes) cooking needs.

The three T's as explained by Dean Still, Aprovech Research Center in the paper presented during PCIA, 3rd Forum (20-23 March 2007), Bangalore India. The CO and the Particulte matter - harmful pollutants can be reduced by burning them before the exhaust cools down for which, the three T's Time, Temperature and Turbulance play an important role, as seen in this model.